About

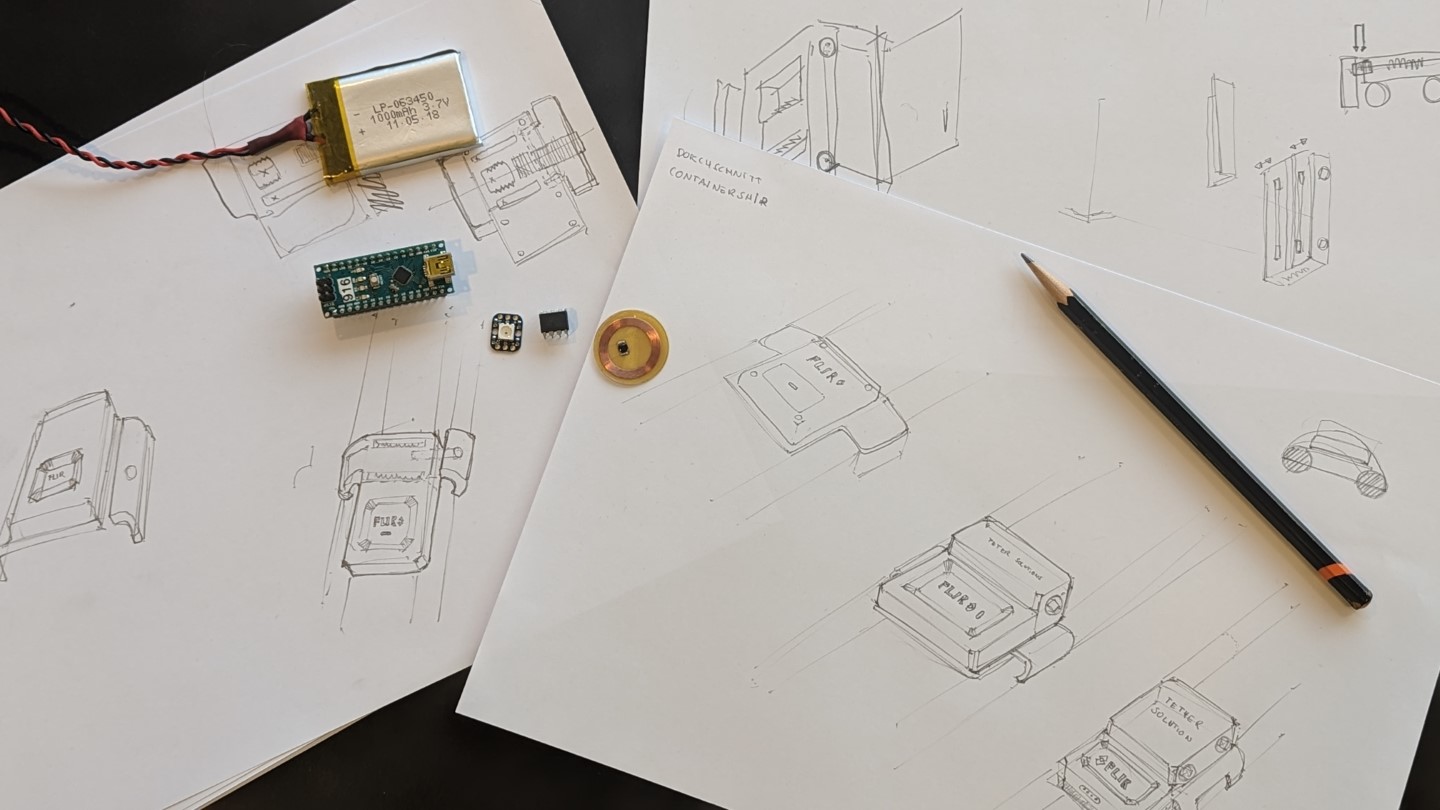

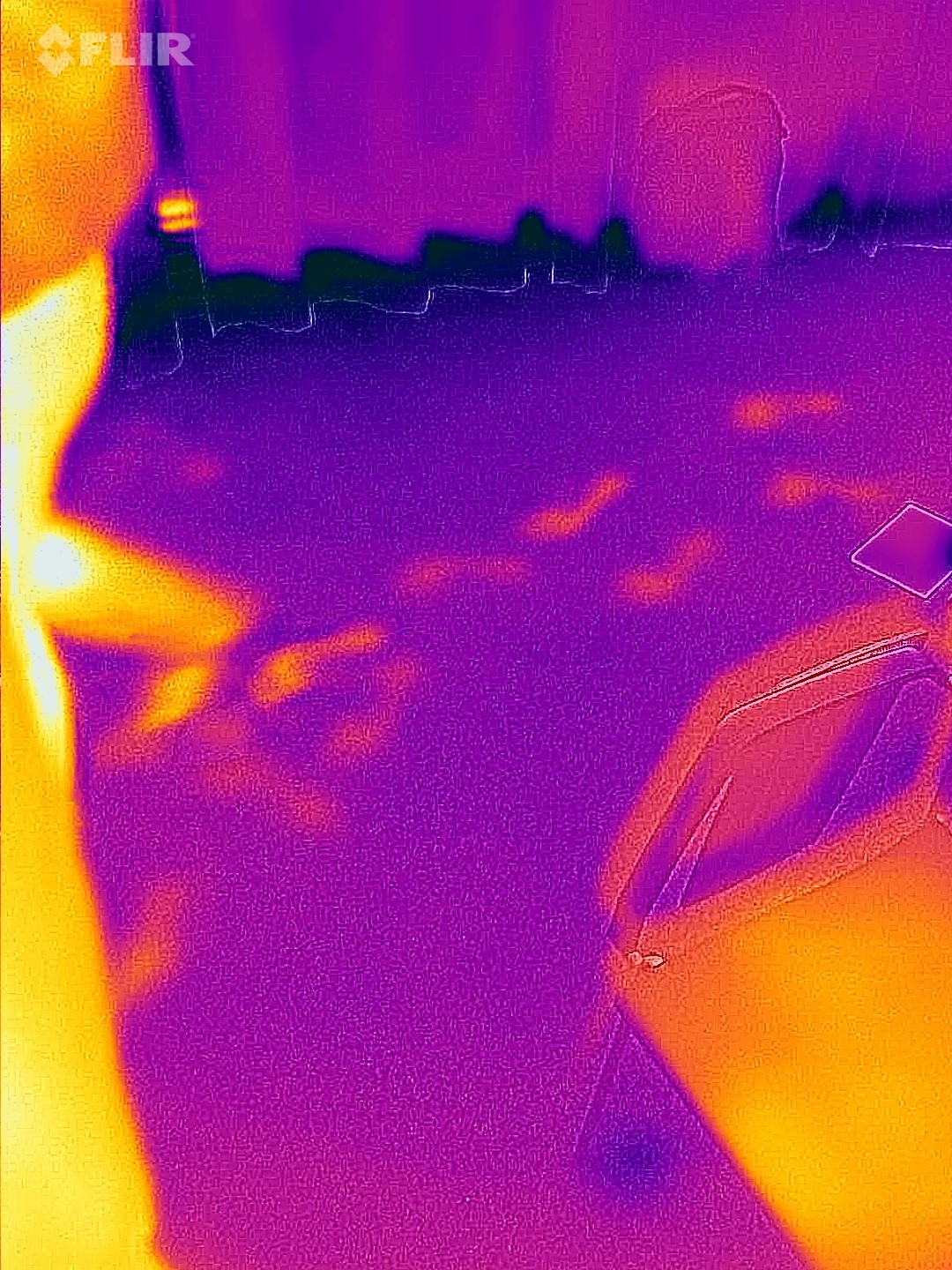

Thanks to the collaboration with the FLIR, one of the global market leaders in thermal imaging, we had the opportunity to explore possible new market segments, all under the umbreall of "showing the invisble", similar to what they archive today with their thermal cameras.

Goal

Finding a product category that fits the FLIR vision and product appearenc. In our case archiving the ruggedness that is required to deploy a longlasting product at sea.

Outcome

With containerships getting bigger and bigger, it is impossible to overview everything. FLIR TetherSolutions is a messuring and early warning device that is deployed on container ships to avoid colapsing container towers, that might injure workers or result in containers going overboard.

FLIR TetherSolutions - Saver

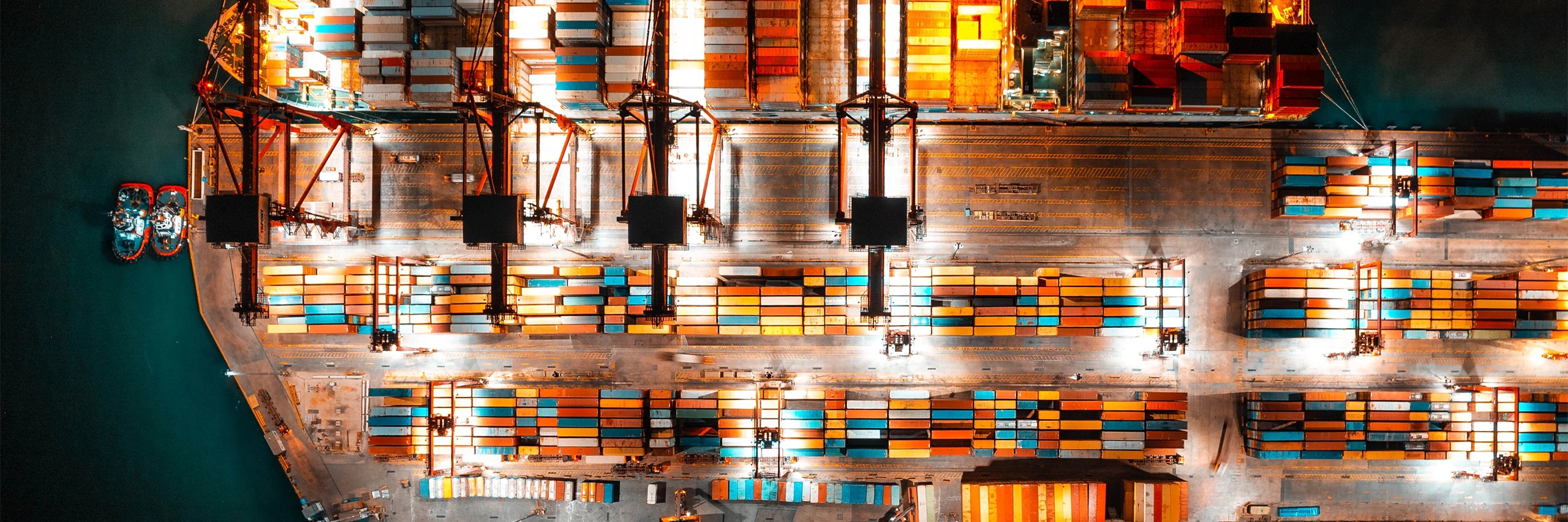

container cargo

10 Weeks Project

2023

Umeå Institute of Design, Sweden

Team Members: Niklas Andreasen, Ellis Walker

80% of world trade is done via cargo ships - 180 Million containers per year

UNCTAD, United Nations

How did we identify the need for FLIR TetherSolutions?

Less personal - more containers

Containership capacity has grown up to 24.000 containers per ship. 1/3 of these containers are stored above the ships deck. The mounting hardware that is used to secure these to the ship should be checked twice a day, a feed that has become impossible for the few crew members.

Financial and environmental impact

The financial damage from containers going overboard adds up to 327 million dollars every year. This ignores the much bigger number of losses due to collapsed containers on the ships and the environmental damage from what was stored in these containers.

Prioritizing Savety

With 20% of all accidents on containerships beeing related to container mounting, it is

the #1 cause for crew member accidents.

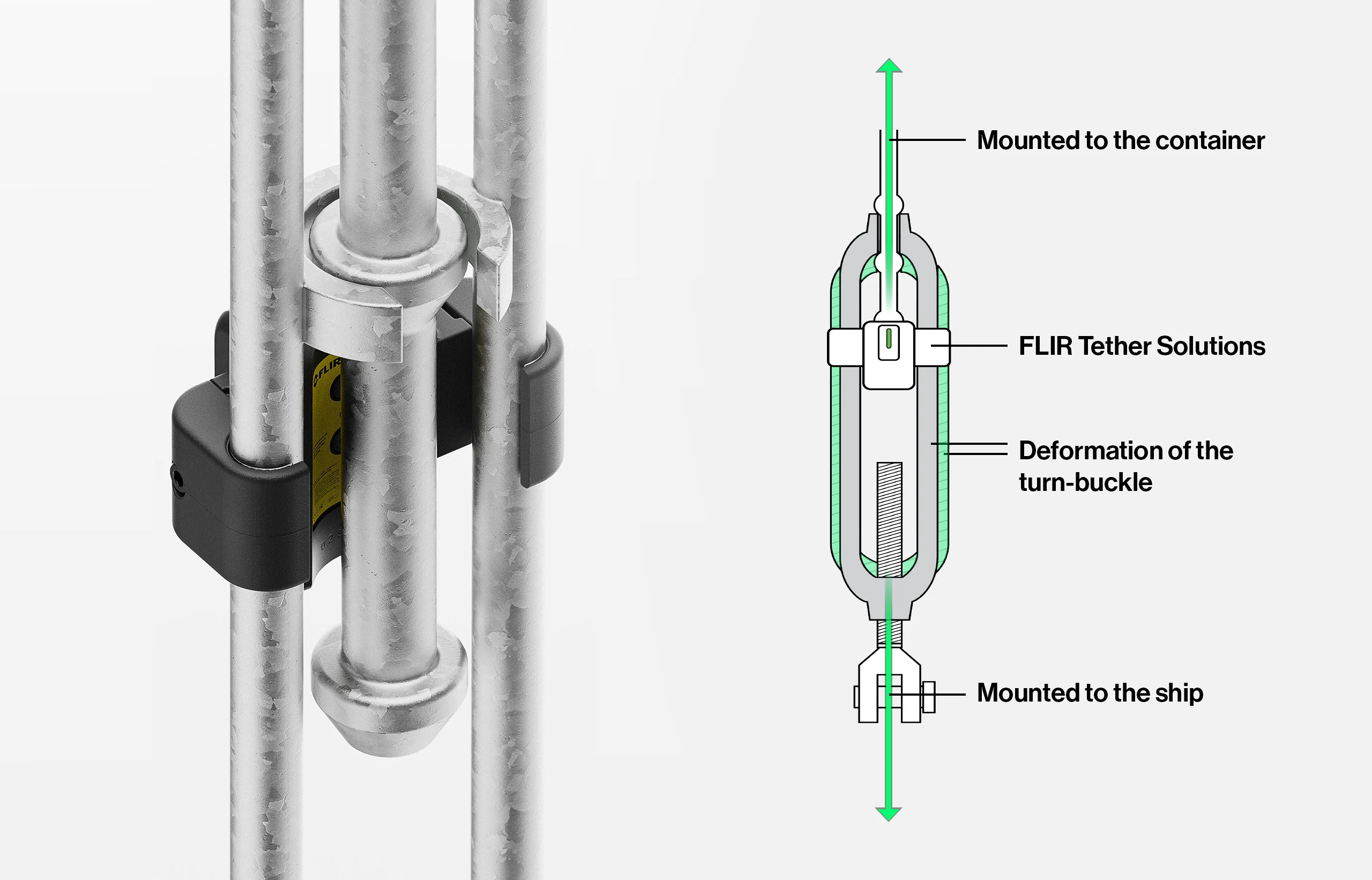

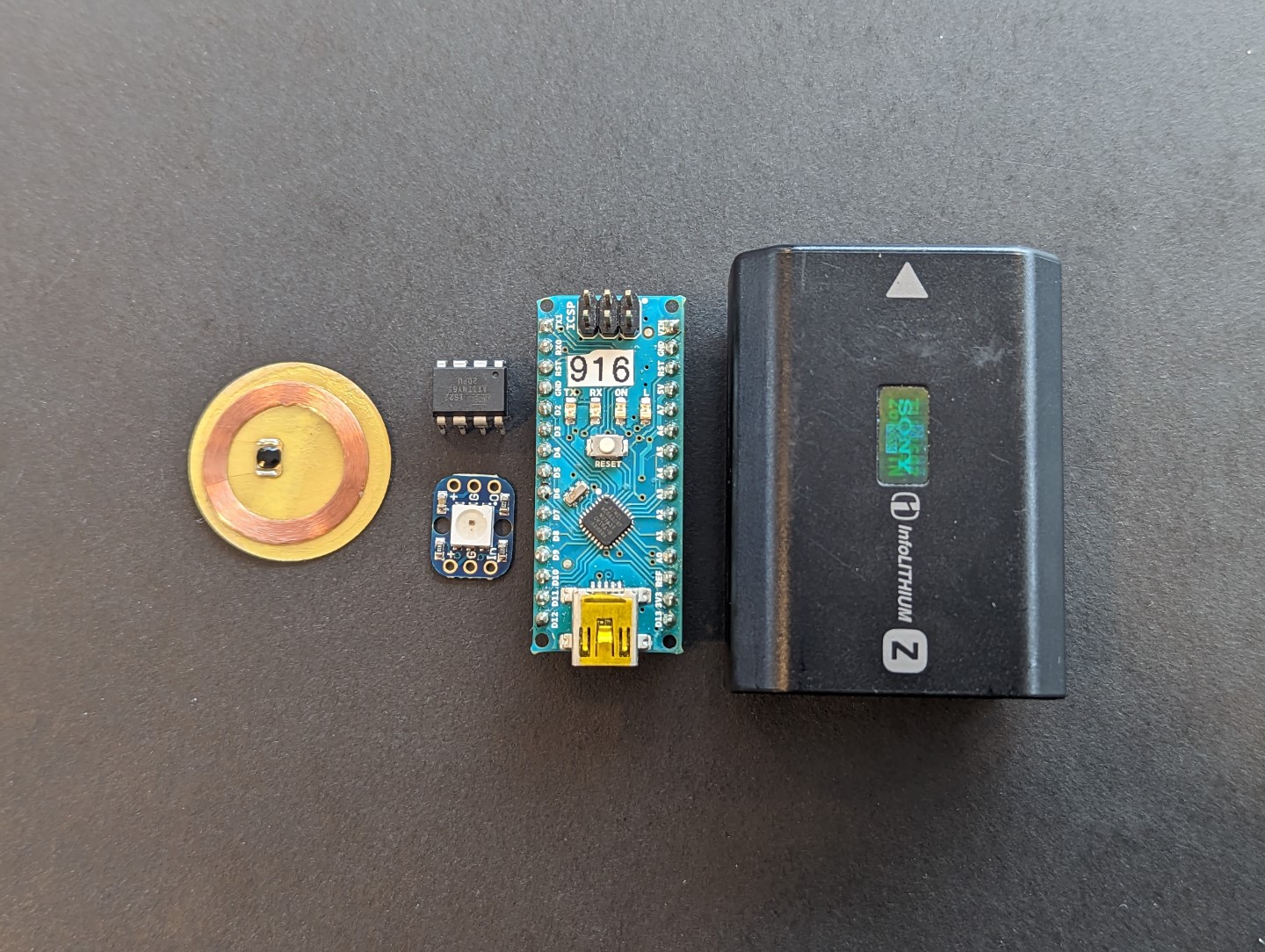

Communication Core

Perfectly protected from any impacts and the elements the communication core establishes a low energy wireless network, to messure and then communicate whenever one of the fastening points loosens up over time.

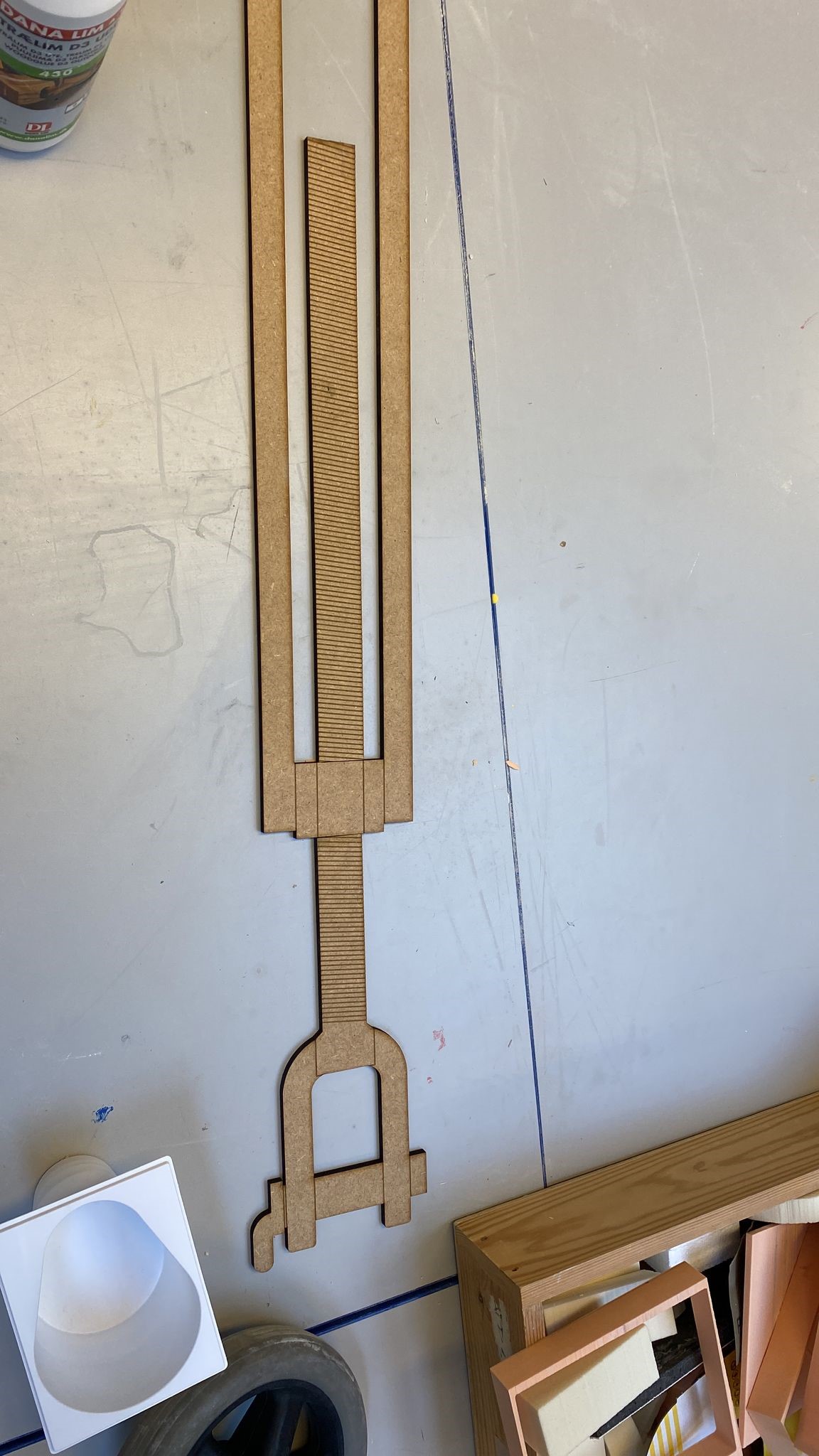

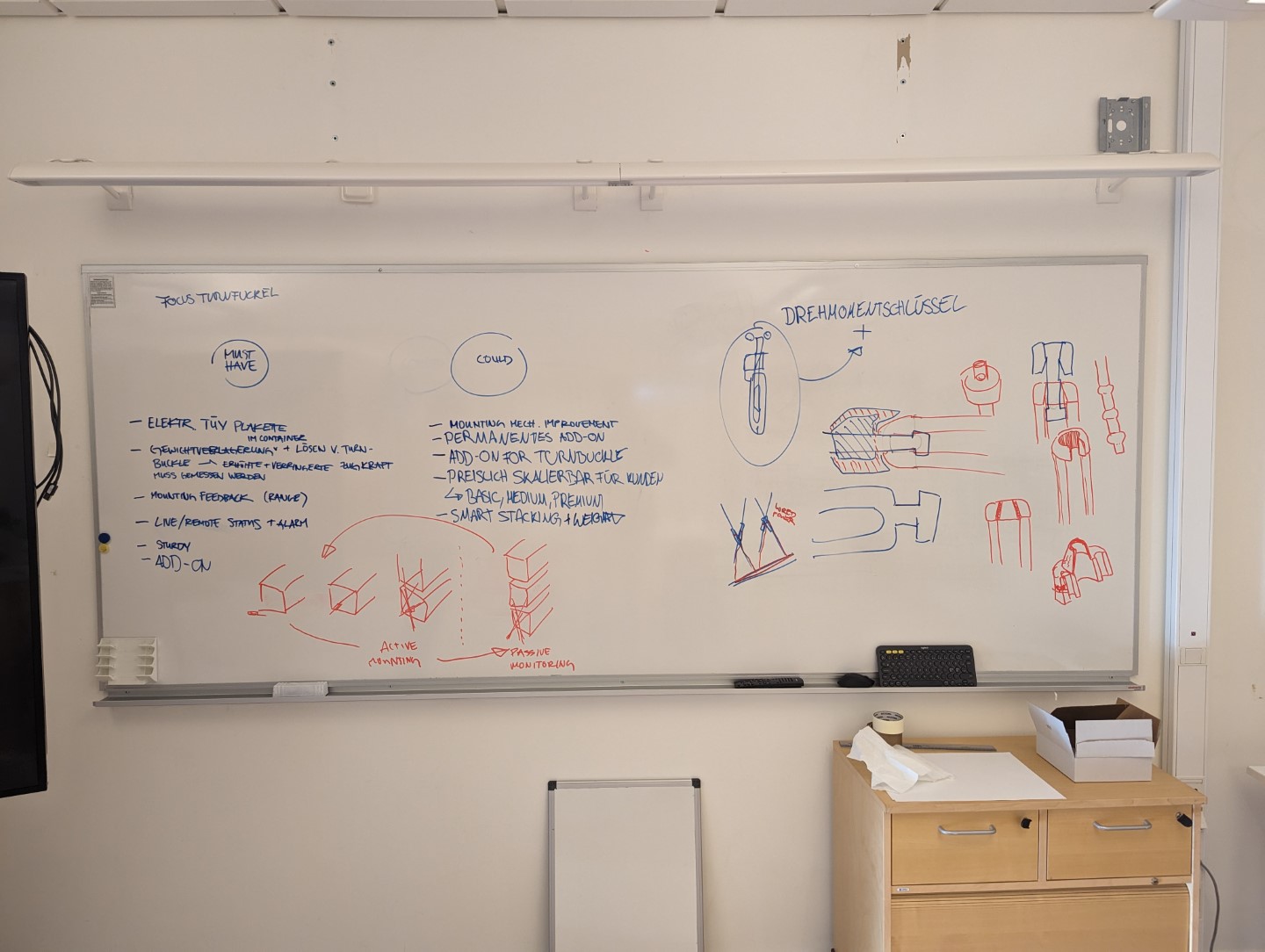

Adaptable Shell

The fastening tool that is most commenly used is called a turnbuckle, they all follow the same principle but come in different dimensions, so our shell has to adapt to that. Thats why we offer different clamps for different turnbuckle models.

Rugged Housing

The housing of FLIR TetherSolutions is made from heavy duty casted metal, to withstand the rough and constantly changing weather of the high seas. Moreover the housing is not supposed to be removed after the initial install, so it also has to keep up with the impacts during the container securing process.

Long lasting energy

To gurantee long lasting battery life (up to three years), the wireless network that FLIR TS establishes only needs to reach the next FLIR TS, which then relays the information until it reaches the central hub, creating an IOT grid across the ship. The messuring intervals can also be adjusted depending on for example the weather conditions to further save energy.

Established Technology

To messure the status of each lashing rod, FLIR TS uses well established technology. At the core of it lays a simple strain gauge, a simple sensor that can messure expansion and compression. These sensors have been used for decades to messure even smaller movments for example the expansion of cranes, buildings and bridges during changing weather conditions and different seasons

How does TetherSolutions work?

Messuring Tension

The turn buckle (displayed on the left) gets mounted to the container on one side and to the ship on the other side. This results into a pulling force in both directions (arrows) - similar to when you stretch a rubber band between your fingers. The turn buckle deforms in a similar way to the rubber band, it gets streched, just on a much smaller scale.

And that very tiny movement gets messured by our sensor,

which then tells the crew, if the turnbuckle is tightened too much or is getting too loose.

© Silvester Kössler

silvester@koe.design

+43 650 977 92 88