Goal

PimaAssist is a smart assistent developed for hospitals, to automatically distribute tasks and therebye minimizing extra work for nurses. The product is currently in its testing phase, therefor the developer needed a housing for the already existing components, that can be produced in low quantities.

Outcome

A 3D printable housing that can be assembled completly without tools.

PimaAssist - Hospital Assistent

2021

PimaAssist

Client Project

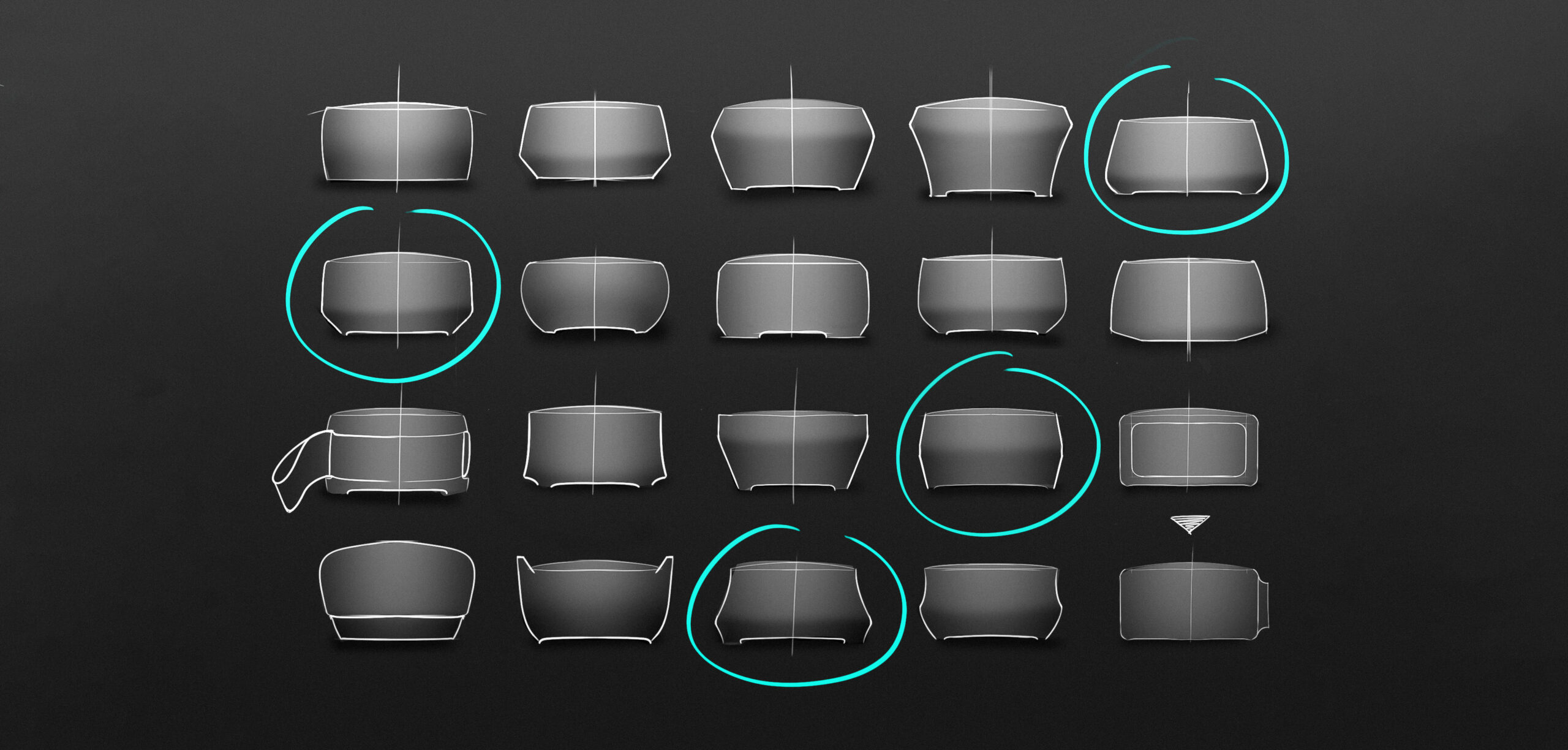

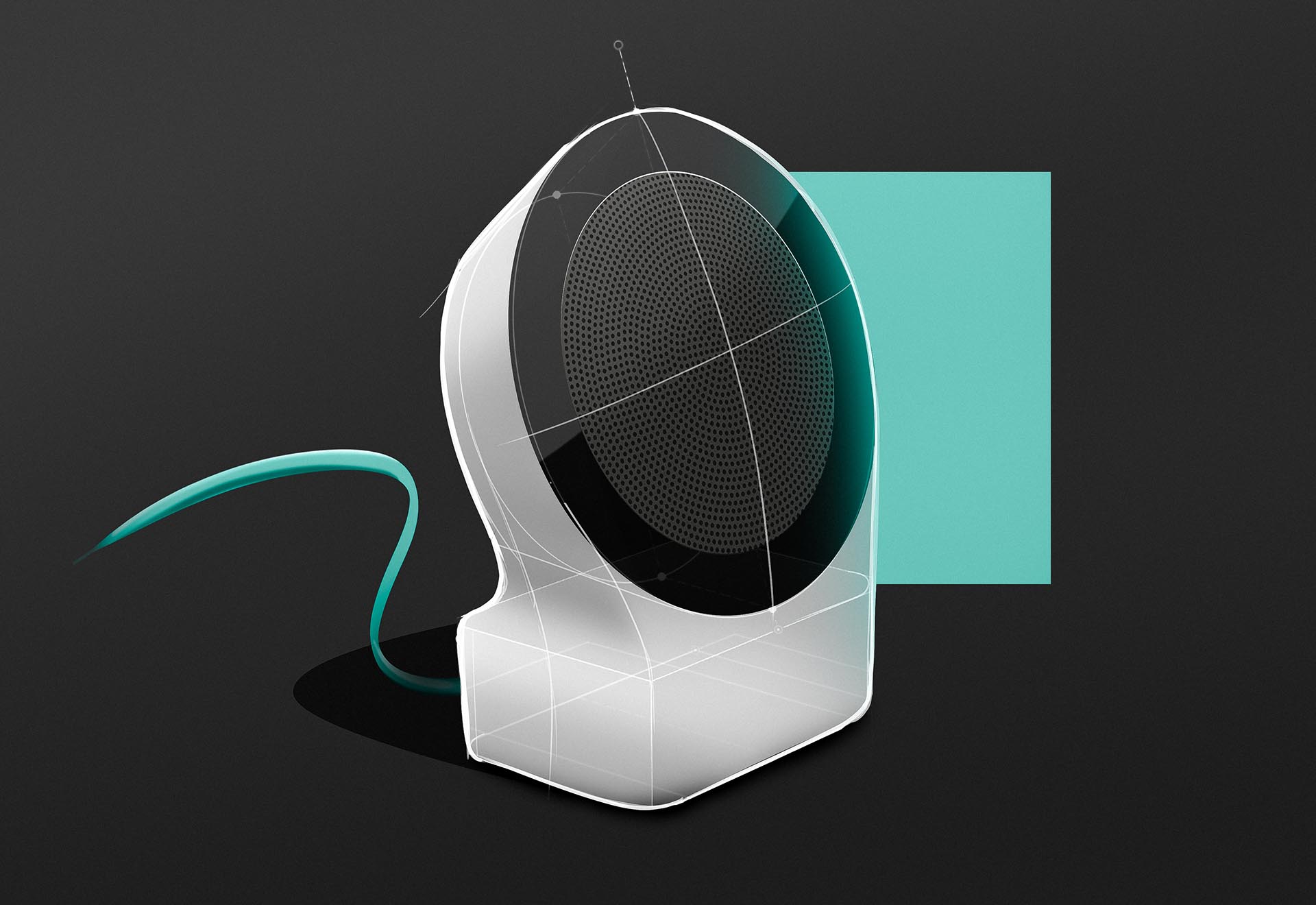

Different Direction

In my opinion a night stand clock like design was interesting for two reasons:

It may look less intimidating to non tech savvy/older patients as it reminds them of something familiar. Moreover it is not the usual rotationally symmetric housing that we are used to seeing from smart home speakers, which would make it stand out in a hospital environment.

Constraints

After carefull consideration the client chose a more classic design. So it was important to show them different versions with different visual weights to get a clear understanding of the final design direction. The maximal diameter and height were predetermined by the size of the two main components.

My true user

Since the patient only interacts with the product through voice commands, my usability focus shifted to the three user groups who interact with Pima Assist® physically: The assembler of the speaker, the maintenance staff and the cleaning staff.

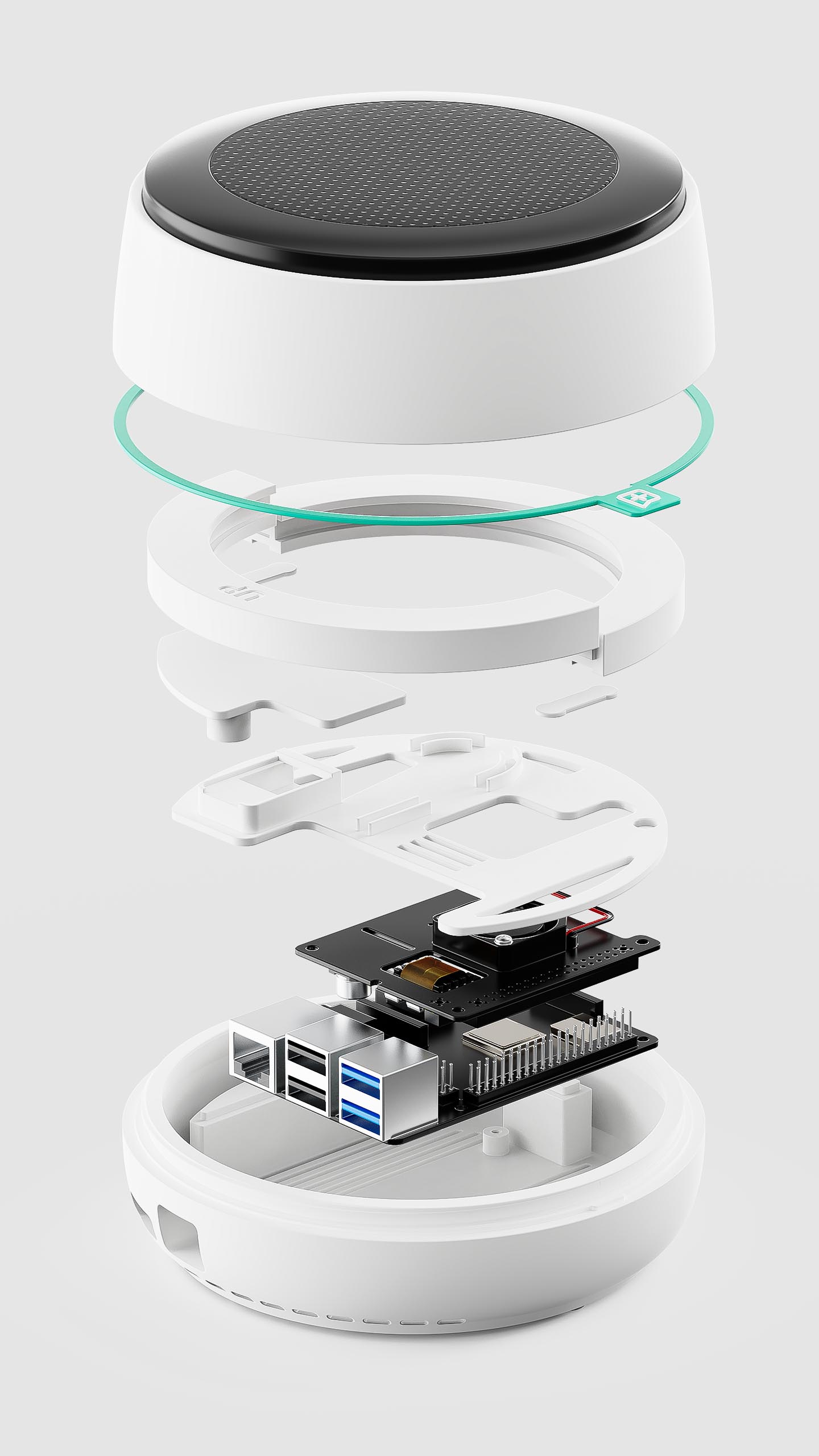

Low Volume Production

With about 300 speakers currently needed a costly method, like injection moulding is financially not possible. With a 3D printing farm just 10km away from Pima Assist UGs office in Düsseldorf, Germany, 3D printing made a lot of sense in terms of production and logistics.

No tools required

The assembly of Pima Assist® is completely tool-less and glue free. All PCBs are pressure fitted with a tolerance of 0,2mm. Both halves have a big thread on the outside, so they can be screwed together by hand leaving just enough space in-between for the colored logo ring.

Further Development

If the regulatory instances at the hospitals approve the new materials I want to further refine the look by covering the speaker with a dirt and water resistant acoustic fabric, which would also cover up the logo of the speaker manufacturer. Moreover the 3D printing manufacturer is currently expanding to offer professionally painted parts, which would further improve the look of Pima Assist®.

© Silvester Kössler

silvester@koe.design

+43 650 977 92 88