Goal

The Austrian Federal Railways (ÖBB) initialised a project with one seemingly easy task: How can we breathe new life into one-track railways in rural areas?

Outcome

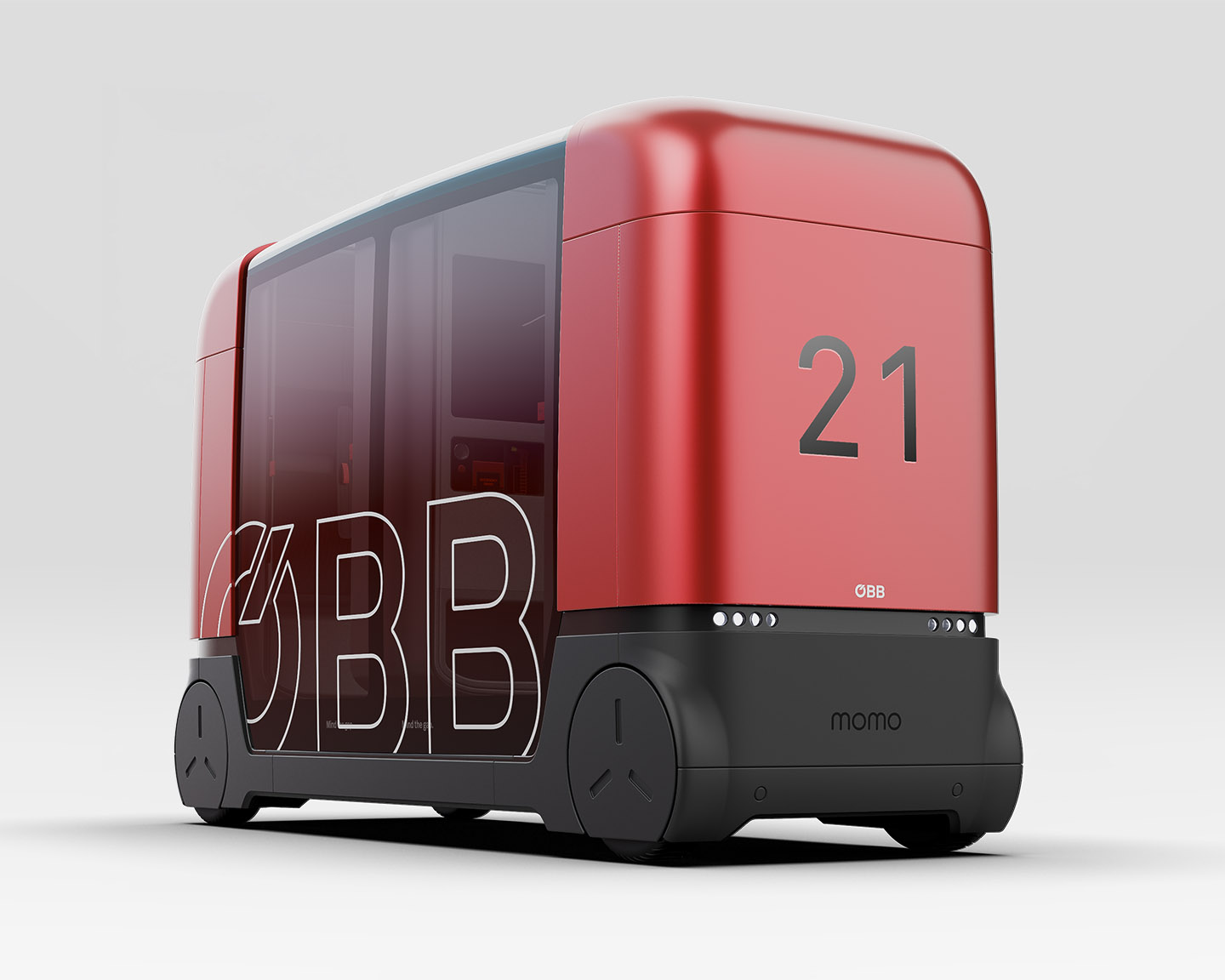

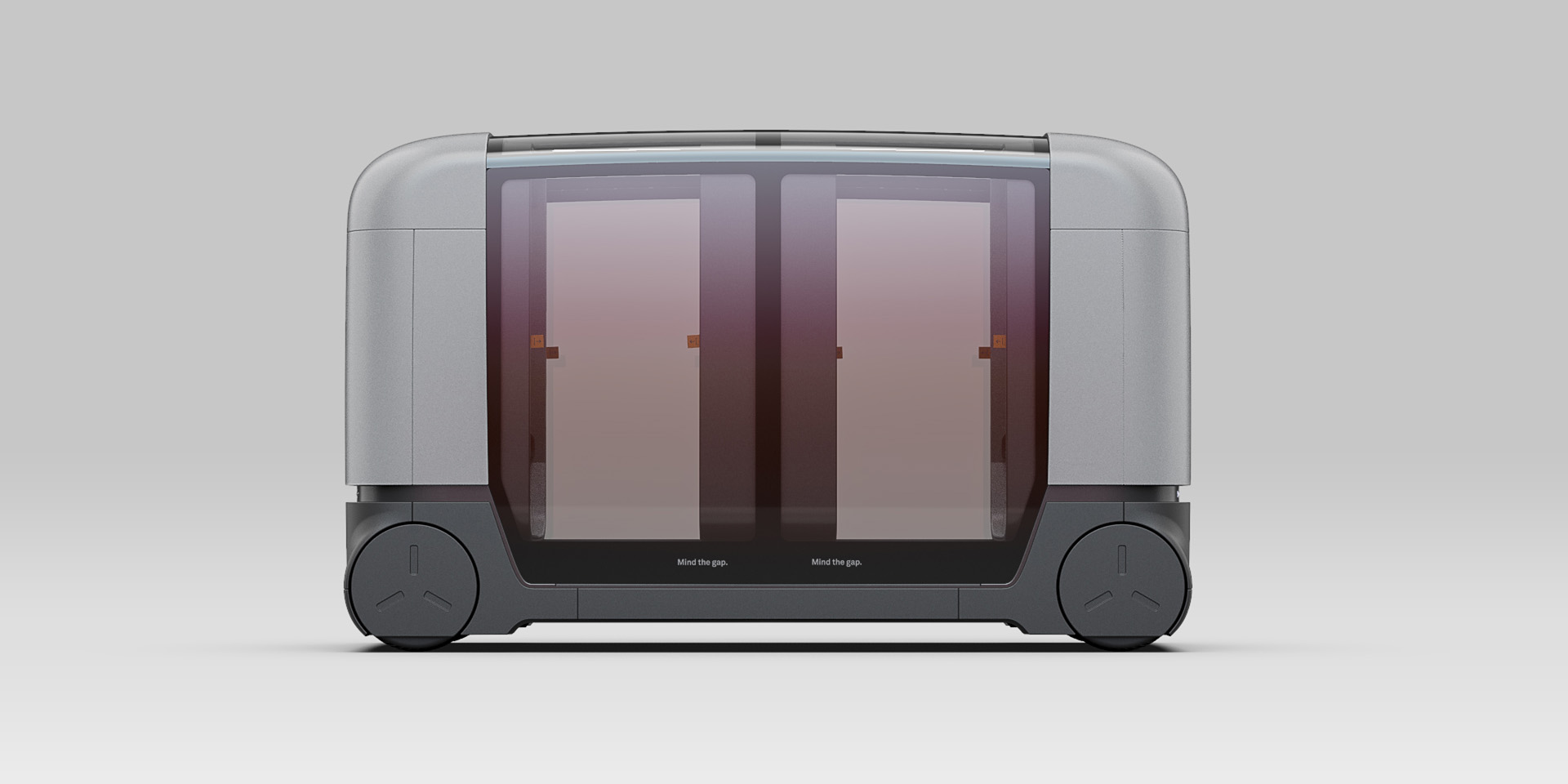

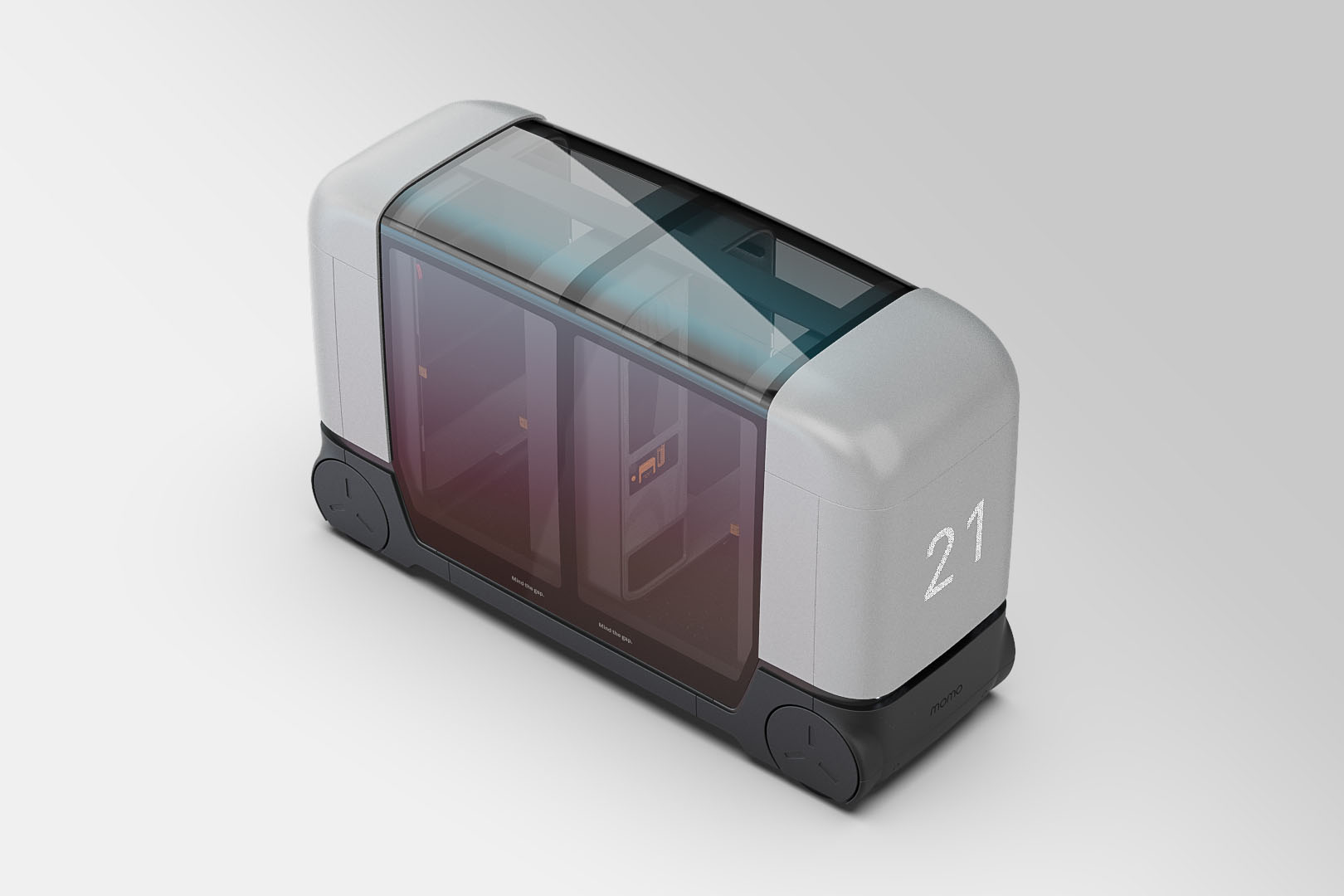

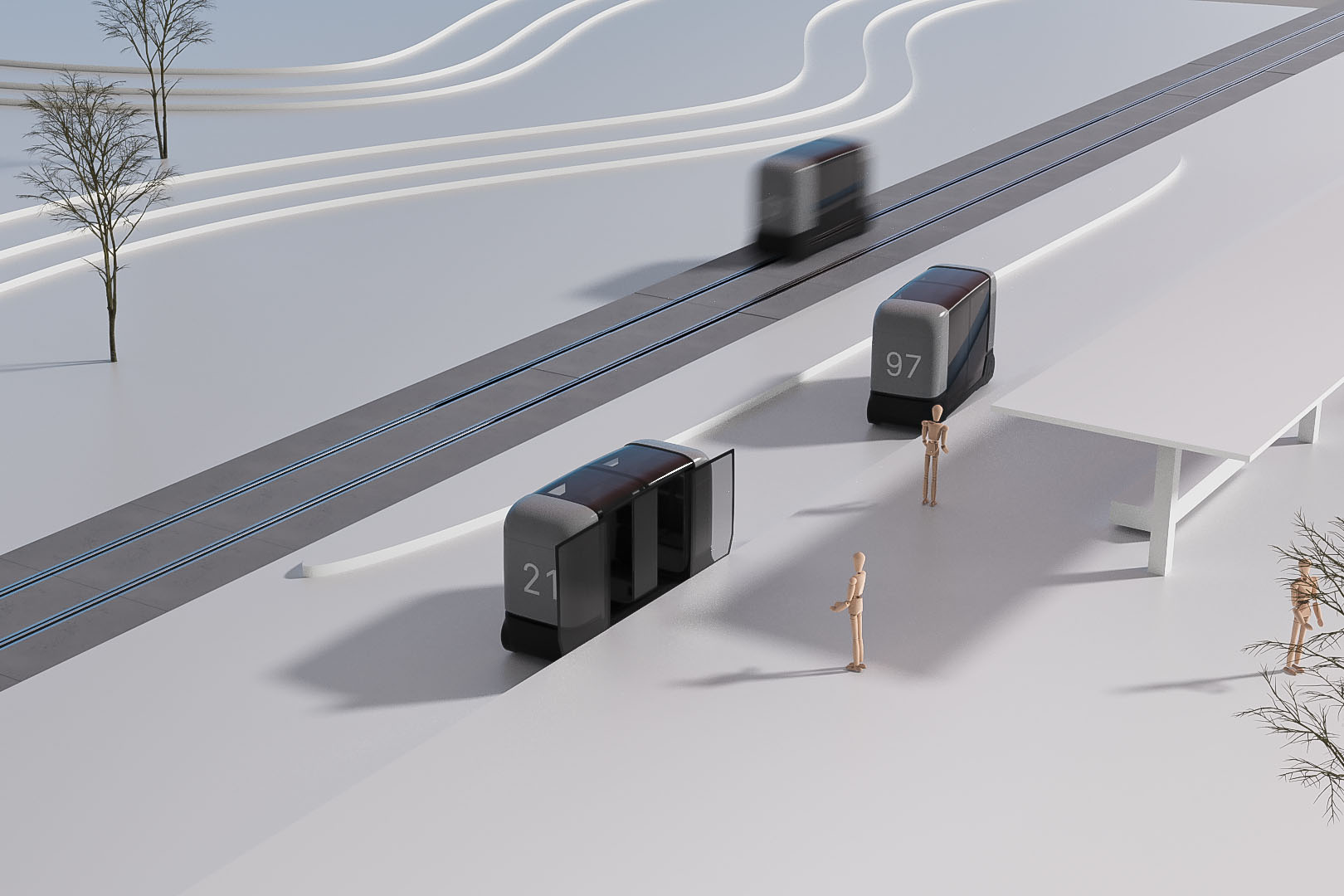

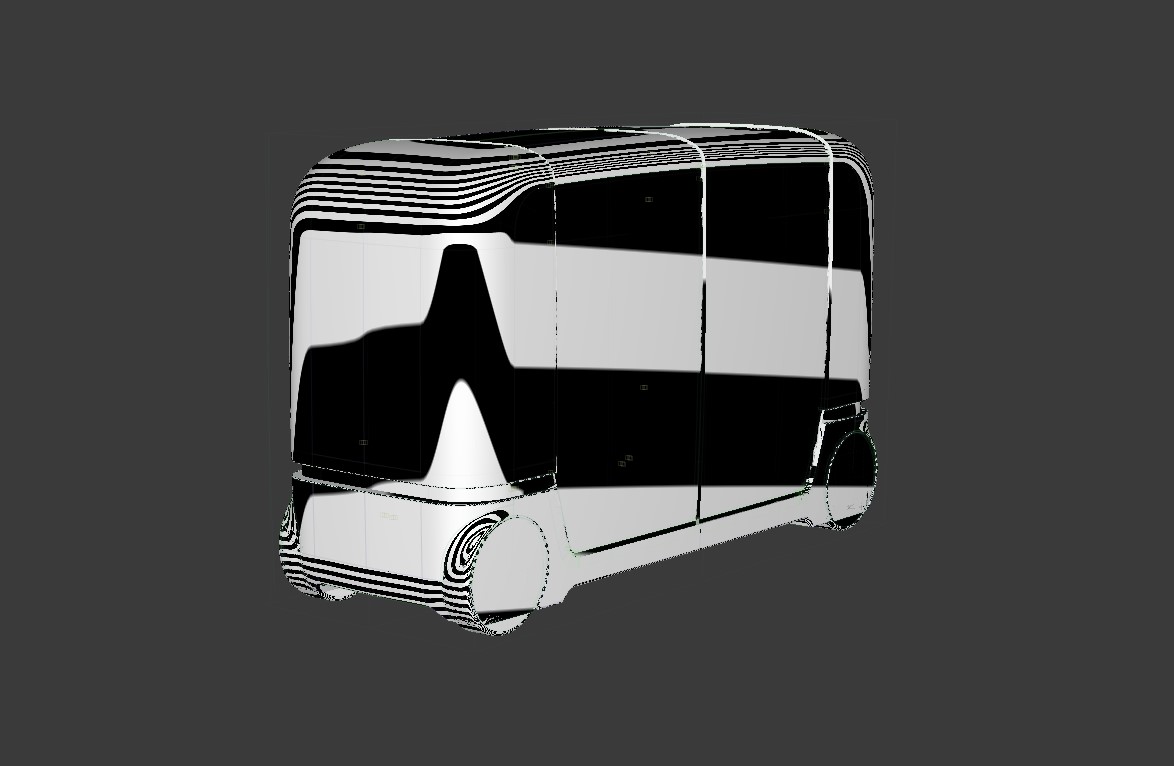

Our answer was momo, a system to utilize the existing train tracks with less constraints outside of the rush hours. Offering the same comforts, like a max. 10 minute waiting time, as we are used to from city center infrastructure.

Momo - More Mobility

Semester Project

Partner: Austrian Federal Railways

2020/21

University of Art, Linz, Austria

Team Members: Martin Peinelt, David Wolkerstorfer

Utilization - Operator Problem

A regular train needs a certain utilization to be environmentally sustainable and cost effective. In rural areas this is only the case during peak hours or when moving heavy freight.

Availability - Customer Problem

A single track can only be used in one direction, which decreases frequency, resulting in longer waiting times. A fact that dramatically decreases the attractiveness of this means of transport.

Solution

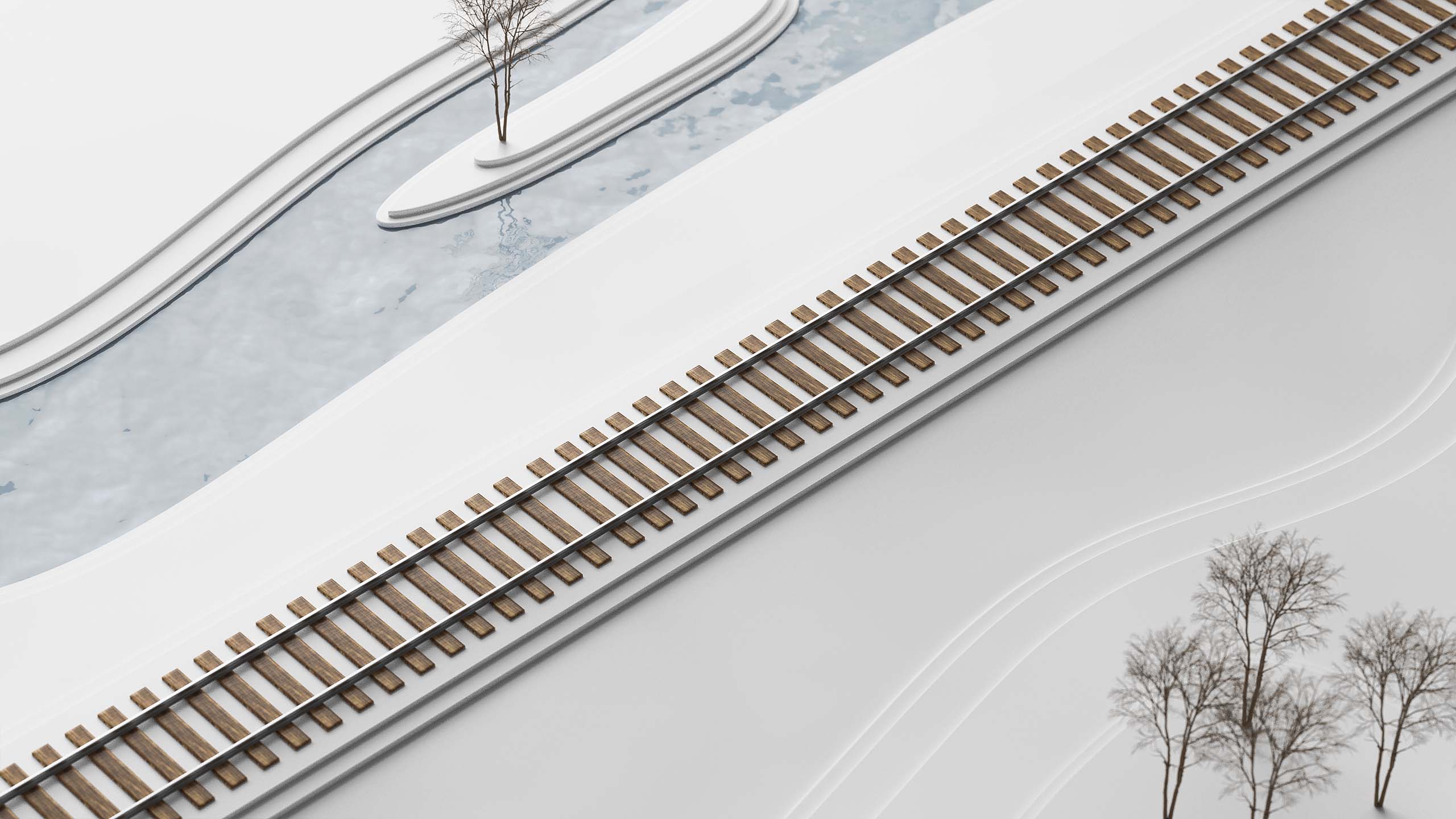

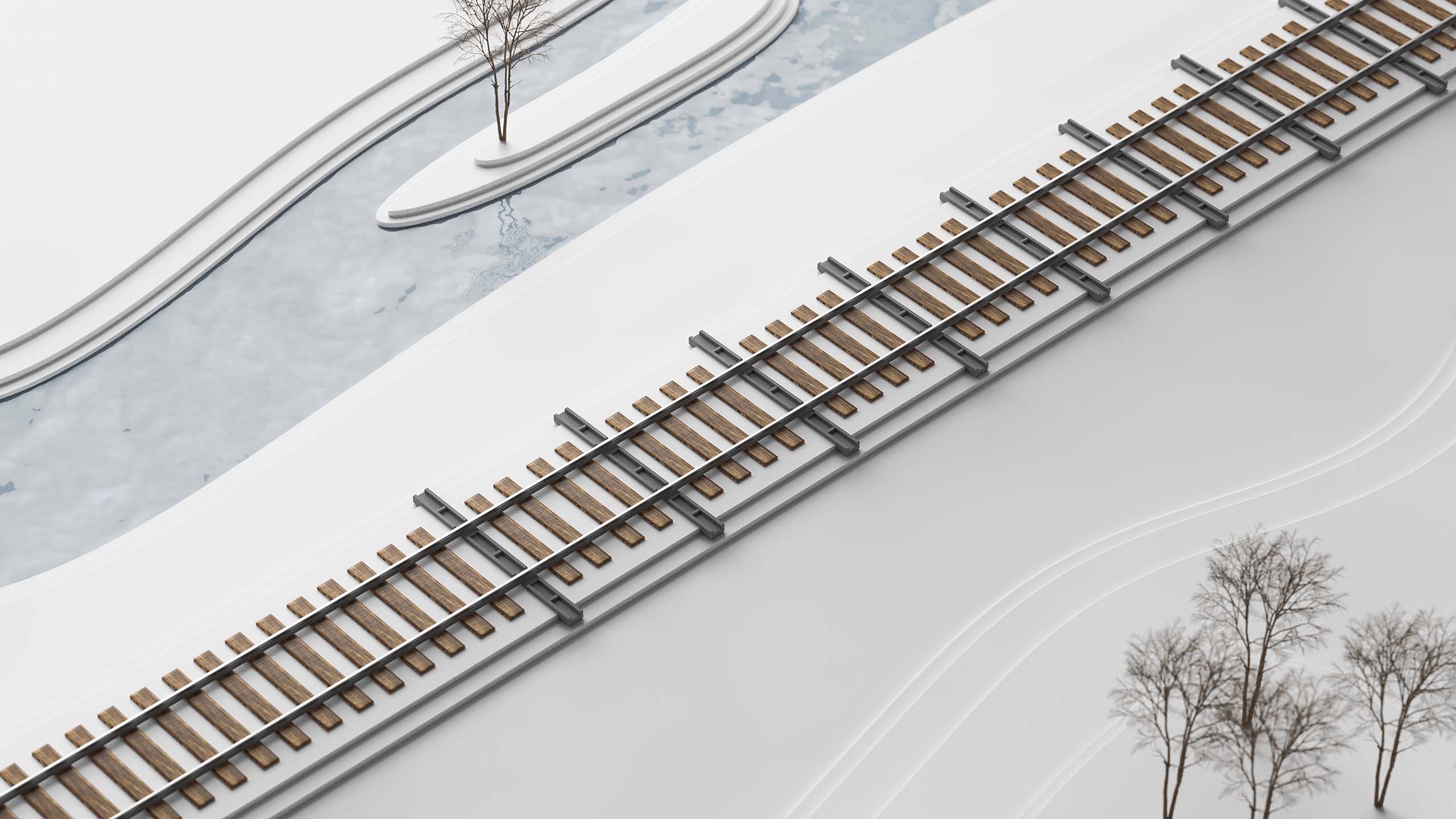

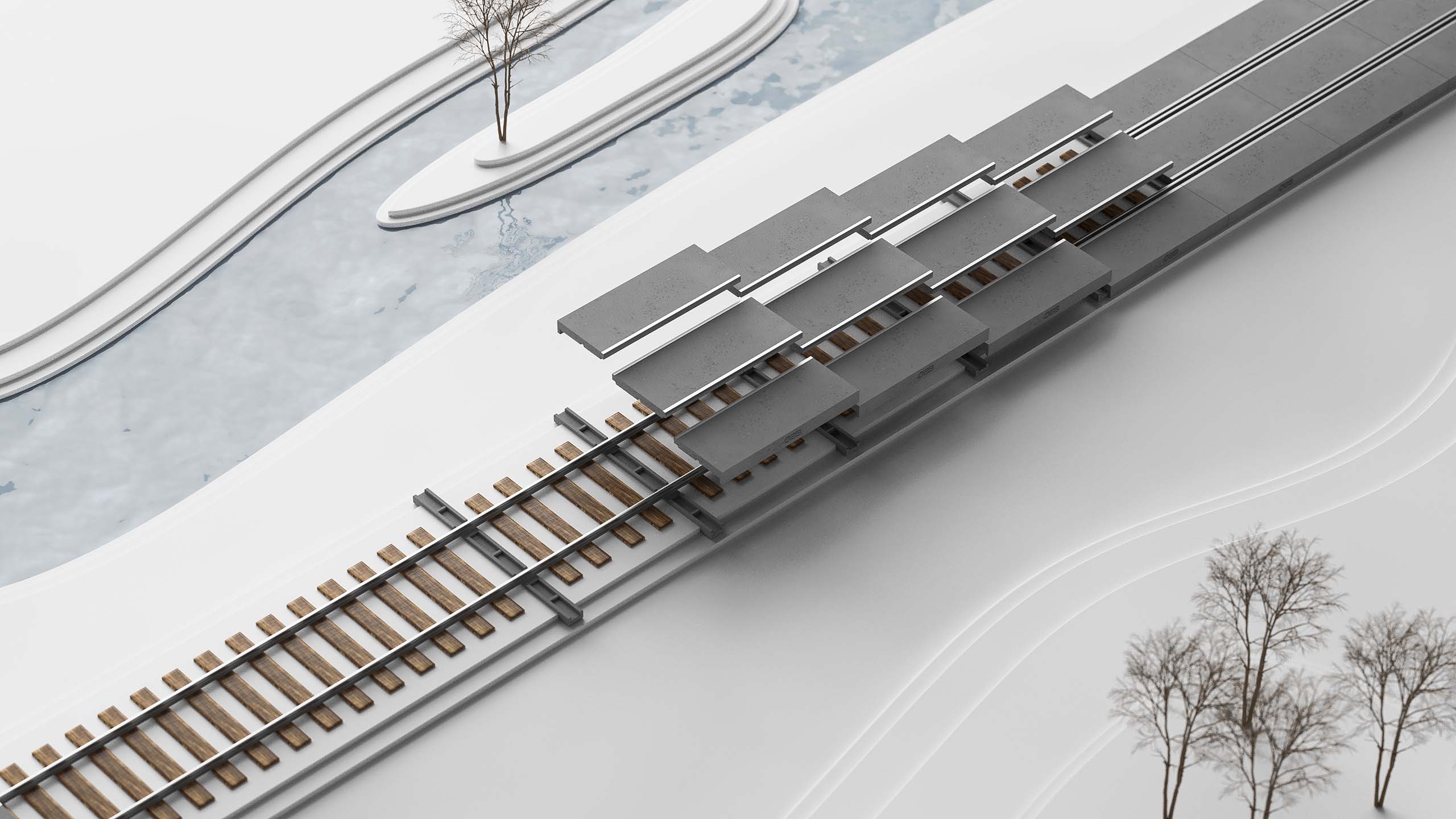

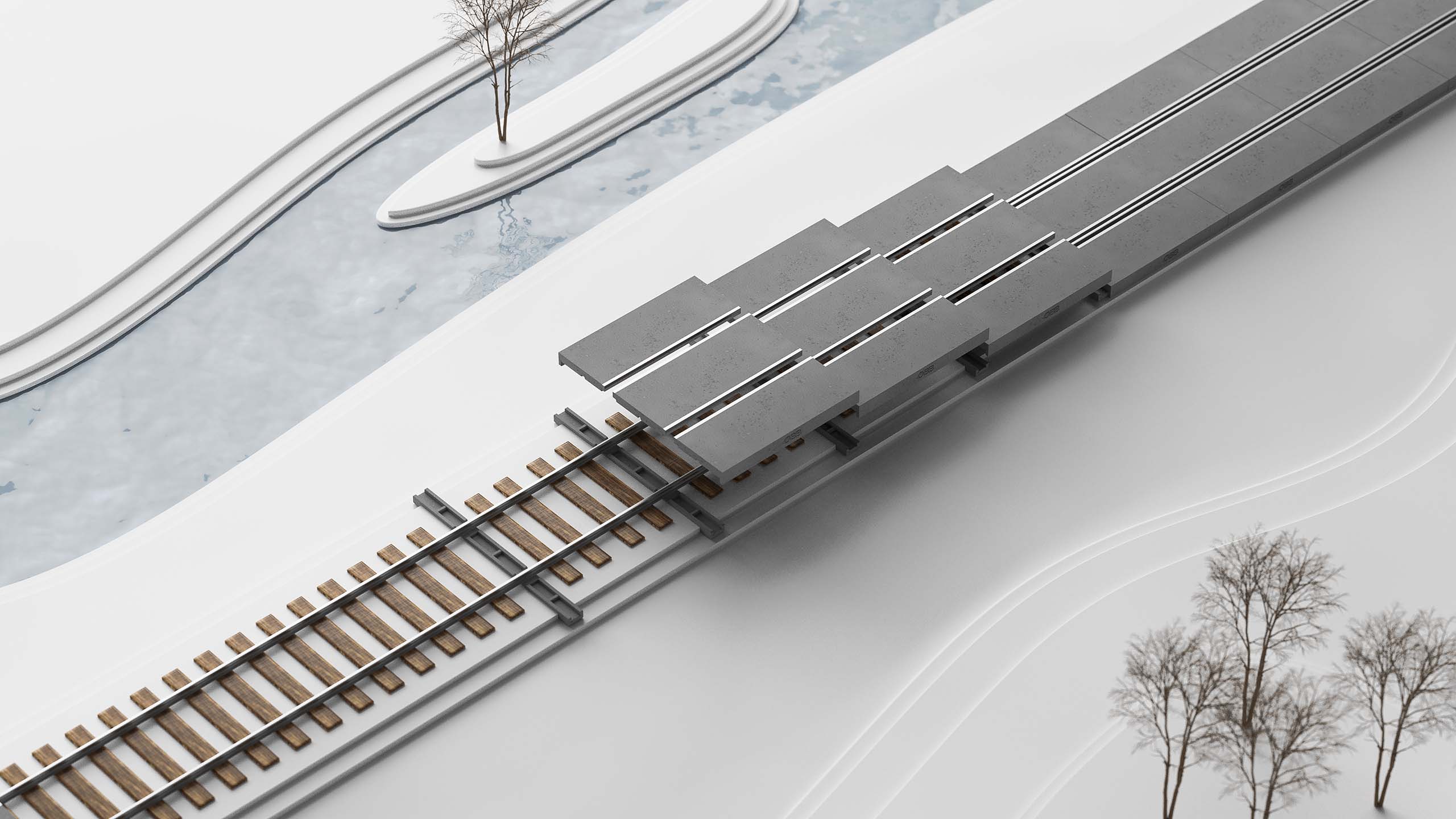

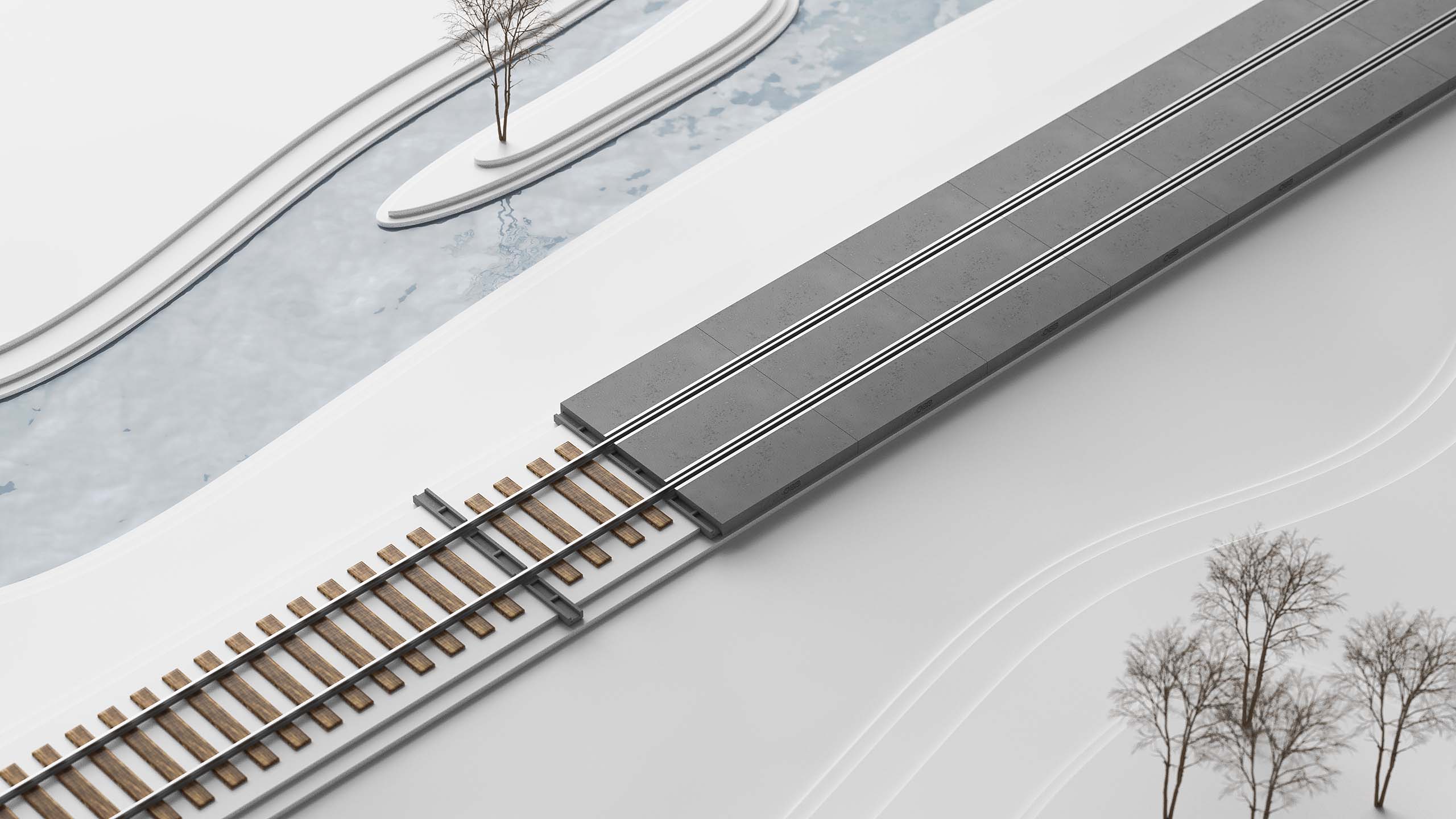

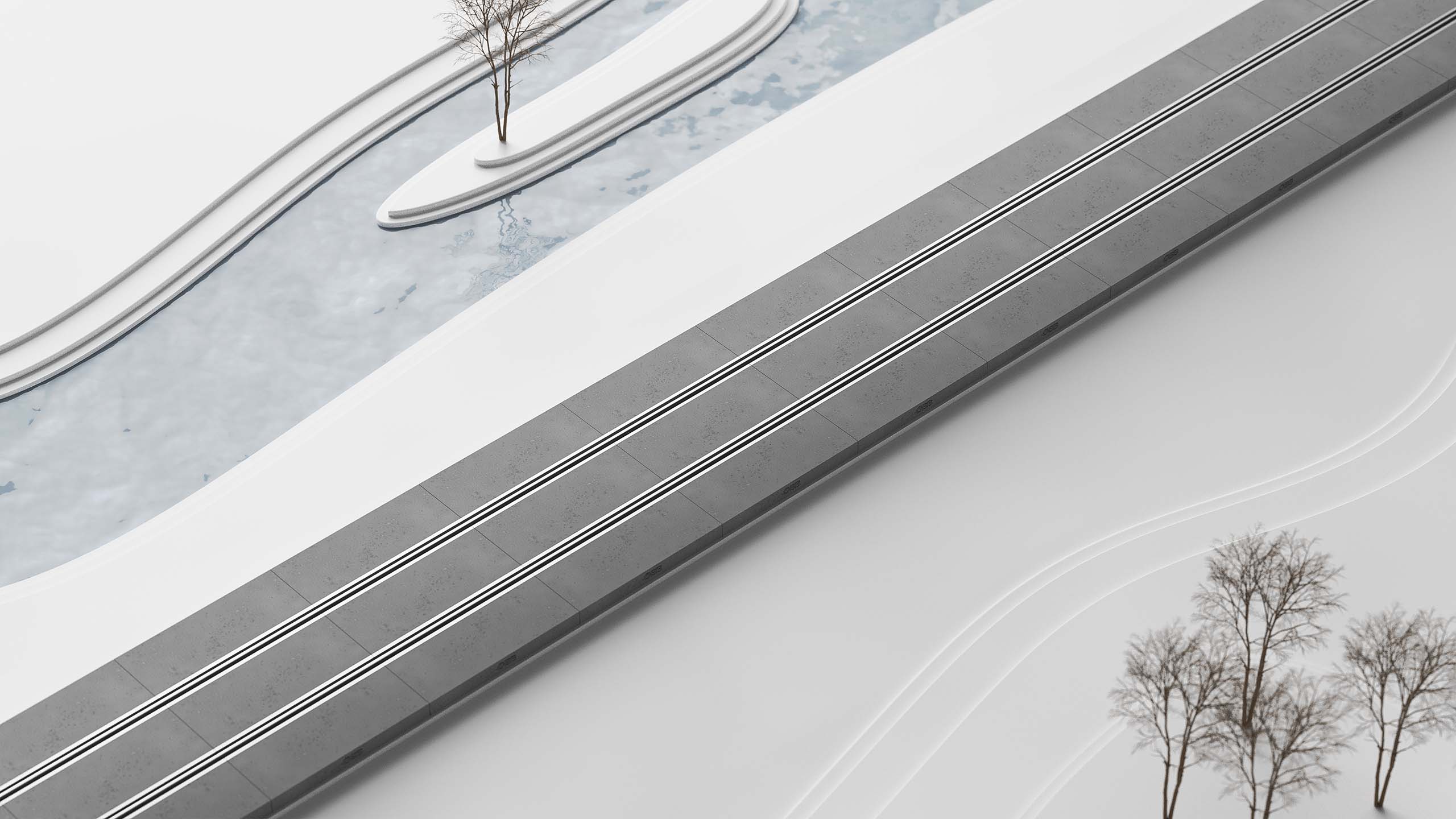

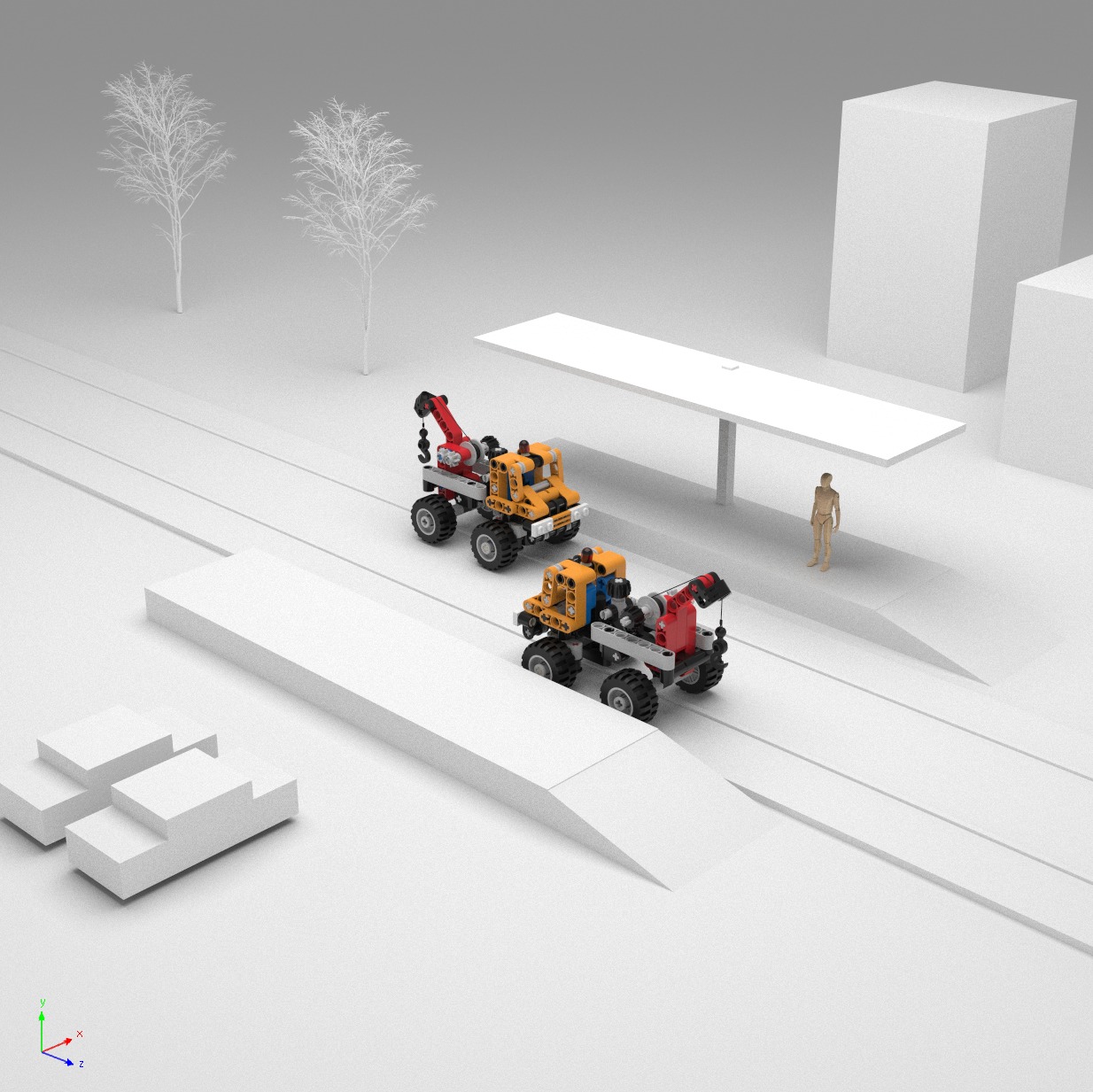

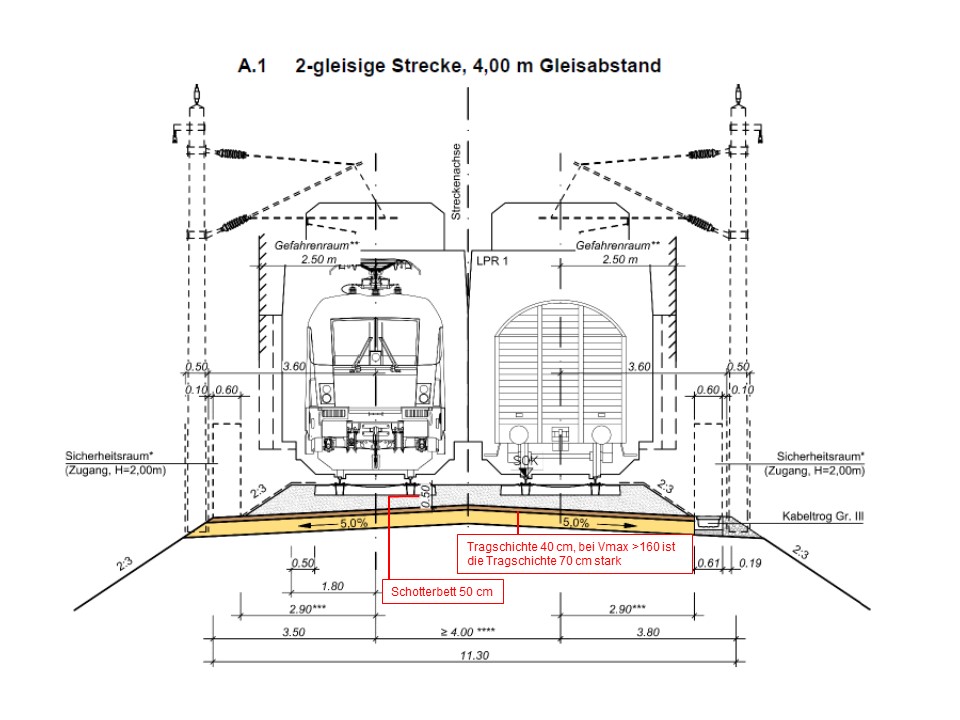

In almost every situation building a second track is not an option, because it is either too expensive or there is no available space. Our solution is a prefabricated component system, which adds regular road driving capabilities to the track. The conversion can be done section by section using already existing train track construction machinery. This keeps costs down and allows a gradual roll-out of the new system.

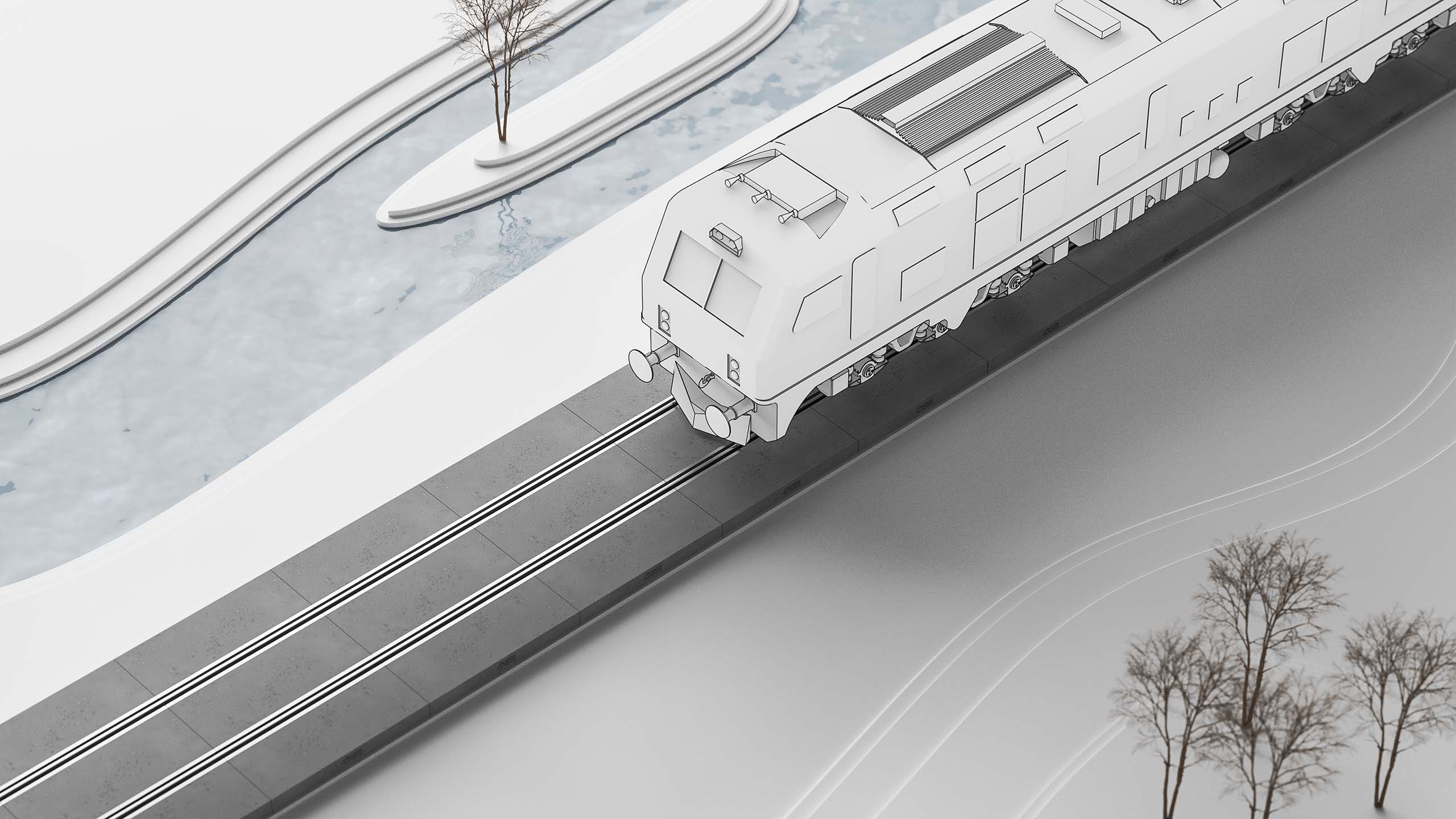

Trains - Highest utilization

Regular trains can still be used to move a lot of people during peak hours or to transport heavy freight. Therefore decades of big infrastructure investments are not rendered useless, making the new system a more attractive investment to the operating company.

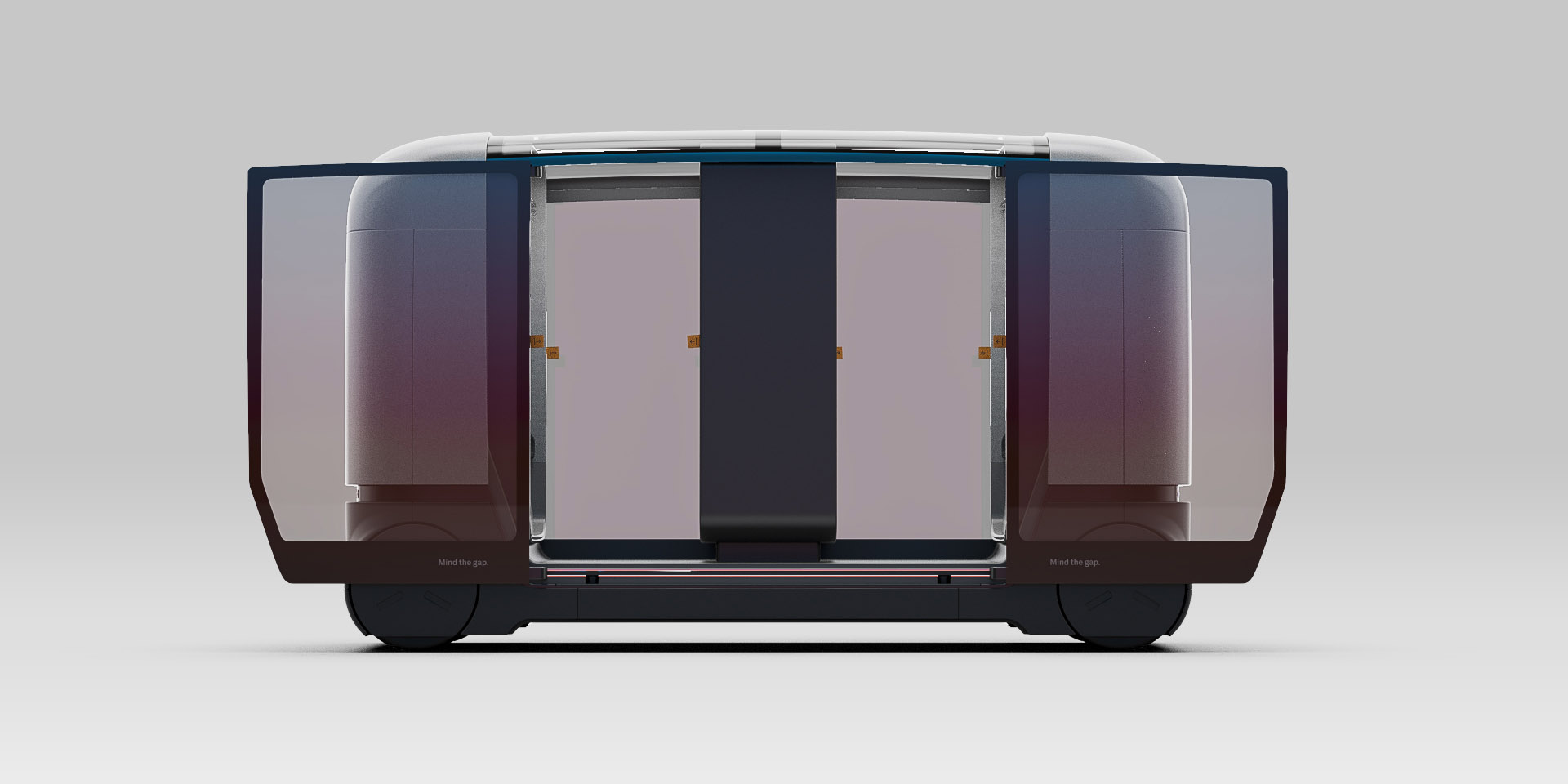

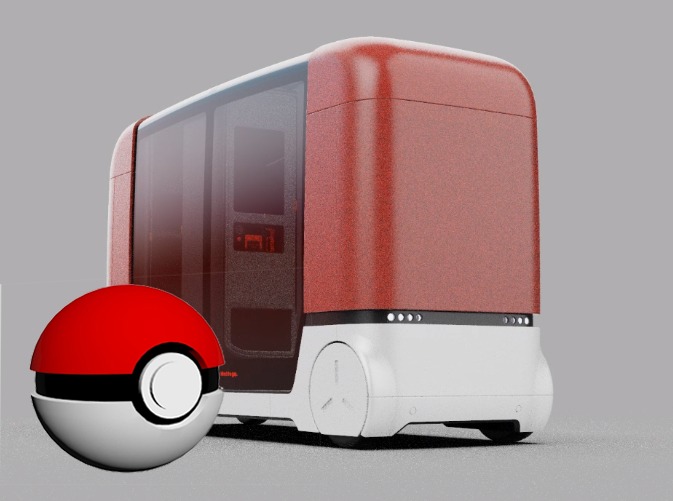

Momo - Ready when you are

With fewer people to transport during off-peak hours a few pods are enough to cover the often short routes, with a 5-10 minutes waiting interval, creating a usability case similar to inner city tram lines. Pods are narrower and can move in both directions simultaneously. Not bound to tracks, pods can easily change direction or leave the track in stations. This allows other pods to overtake them while they pick up and drop off passengers to minimize travel time

Play to your strenghts

Today the biggest hurdle for autonomous driving is mapping and predicting everything around you, like other vehicles and pedestrians. Without any of these obstacles the modified train track is the perfect environment for autonomous driving. Basic sensors would be enough for positioning and collision avoidance. By integrating these sensors into the track rather than into every vehicle, the cost per pod could be reduced dramatically.

Never miss out

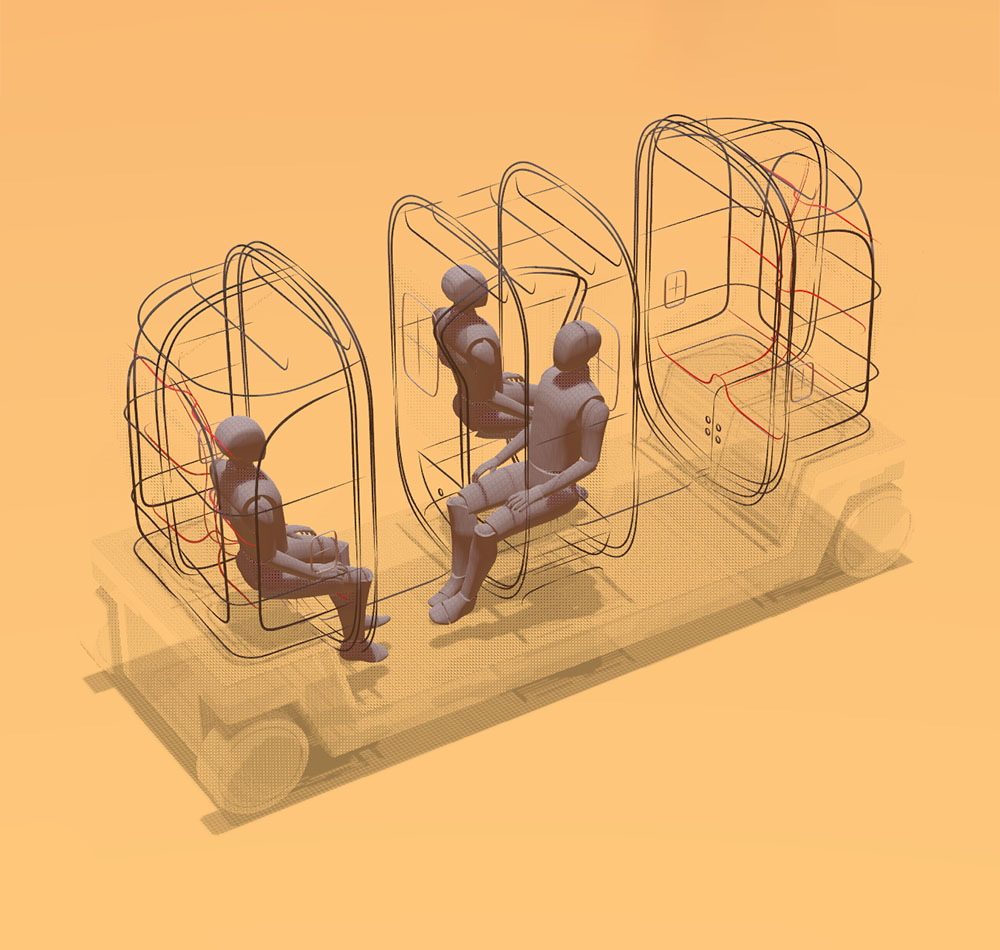

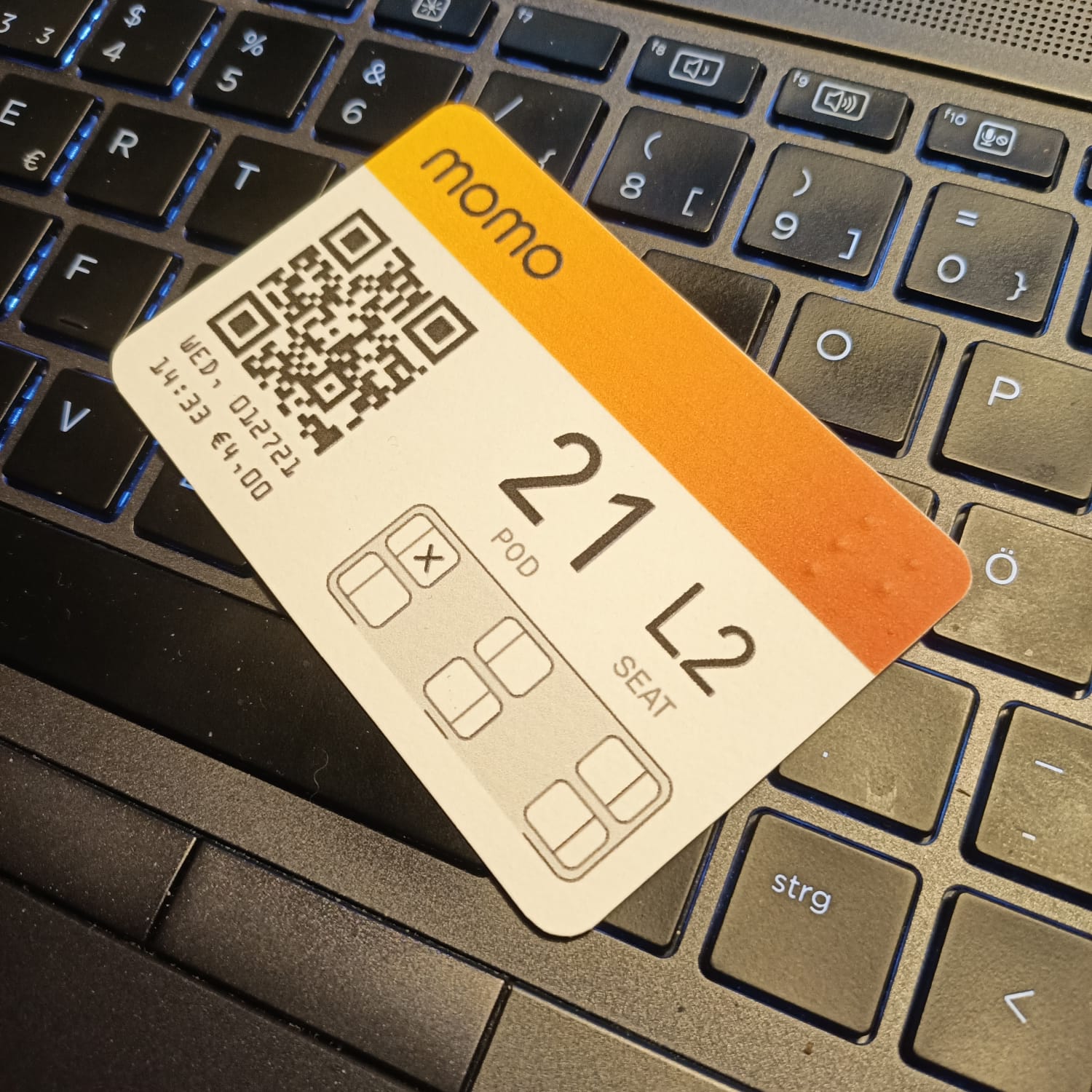

Momo can pickup six passengers. Three in

each section. Most people commute alone or maybe with their partner - why three

seats in each section then? If you travel in a group every size above three can be divided into two parts without ever leaving a single

person behind.

S for space

The big screen shows information relevant to all users in the vehicle, like the next relevant stops where a person is either picked up ordropped off. The small one is for personal infos,

like reminders regarding your ride and to validate your ticket.

Providing information

The big screen shows information relevant to all users in the vehicle, like the next relevant stops where a person is either picked up ordropped off. The small one is for personal infos, like reminders regarding your ride and to validate your ticket.

Visual Trickery

In a small vehicle like momo perceived space is as important as true size. Thanks to the glass shelf of the overhead storage the seating area feels more airy and open.

Using Your Time

Because momo is designed for shorter commutes (20-60min)

a sturdy but easily retractable desk big enough for a laptop or

a sketchbook was essential to us.

© Silvester Kössler

silvester@koe.design

+43 650 977 92 88